Building the Rim of the guitar is actually quite a sophisticated process. After the sides have been bent and allowed to completely dry in the exterior mold, the are fitted at the centerline.

I then glue the tail block and neck block to the sides so they are now one piece together. You will notice here that I’m on a granite slab that is perfectly flat. The jointed edges of the sides (jointed prior to bending) are indexed to the perfect plain of the granite to ensure the rim is built without any distortion.

Here you can see the kerfing has been glued in place. What you can’t quite see here is the radius that has been sanded into the edges of the rim. First, the back would be radiused to 15′, then I would glue the kerfing, and then sand again ensure a clean flush surface to glue the back.

One by one, I carefully fit each brace to the kerfing where they intersect. A good fit ensures the structural integrity of the guitar, but it also helps the guitar, as a whole to resonate together as a single unit.

After all of the back braces are fitted, I begin to fit the soundboard to the rim. Several of the top braces will need to be fitted just as the back braces were.

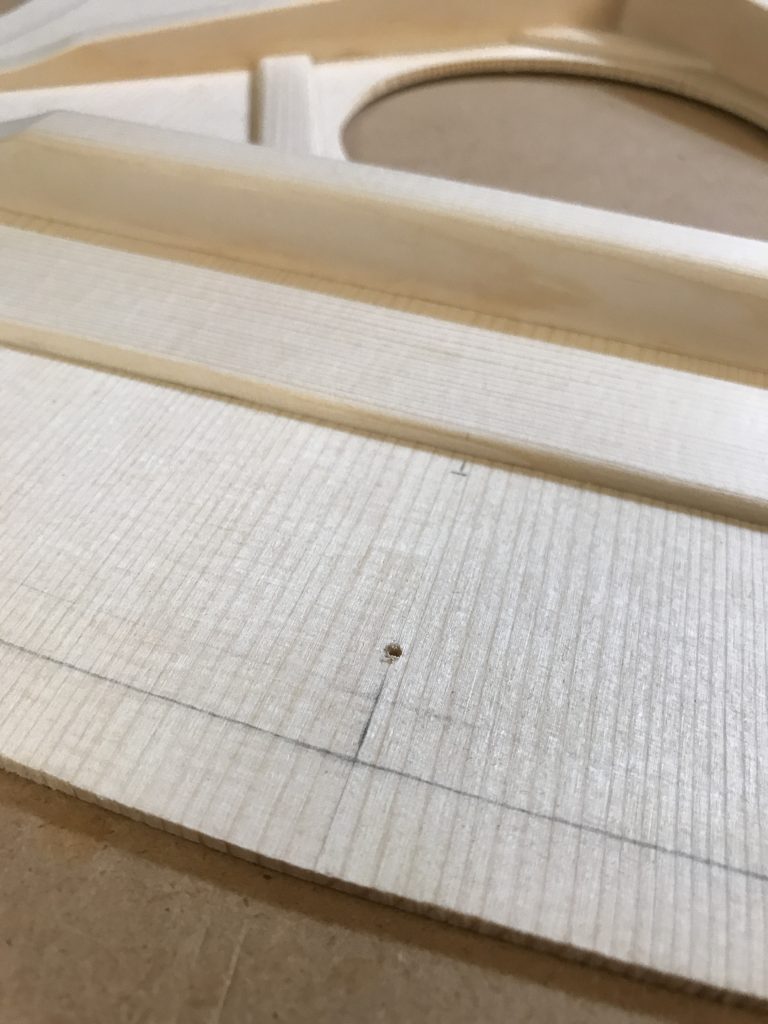

I use an indexing pin to line up the centerline and the placement of the top on the rim and mark each brace, and the kerfing, for fitting

Here you can see the fitted top braces. The body is ready to come together so say goodbye, you won’t see the inside of this guitar ever again!

I glue the back and the top to the rim at the same time. I use radiused dishes as cauls to ensure the top and back have the accurate radius that I have been building into each component every step along the way.

This is probably one of the most satisfying moments when a body goes together so well. A well fitted top and back make a big difference in the life and longevity of a guitar and this one went perfectly!